Aerospace & Aviation

Environmental Test Chambers for the Aerospace & Aviation Industry

Ensure your components soar above the rest.

The aerospace and aviation industries rely on AES environmental test chambers to simulate various atmospheric conditions for testing various aircraft, components, and parts. These tests are essential to ensure that all commercial and military aircraft meet stringent standards and specifications, such as those set by SAE International. By replicating real-world conditions, these chambers help verify the performance and durability of aerospace equipment under diverse and extreme environments.

Quality, reliability, and safety are paramount in the aerospace and aviation sectors. Every component and system must adhere to rigorous quality controls to maintain these critical values. AES environmental test chambers are integral to this process, providing the necessary conditions to evaluate and improve the reliability and safety of aircraft parts and systems.

AES is a trusted partner for the aerospace and aviation industries because of our unwavering commitment to quality and our expertise in test chamber manufacturing. Our chambers are designed to meet high customer safety and satisfaction standards, ensuring that the industries can depend on us to support their rigorous testing needs.

Test Chambers for Aerospace & Aviation: Talk to an Expert

RELEVANT ENVIRONMENTAL TEST CHAMBERS

Temperature & Humidity Chambers

Conduct temperature and humidity cycling testing. Benchtop, stackable, and walk-in room options

Workspace Range: 2 to 264 cu ft

Browse Temperature & Humidity Chambers >Thermal Shock Chamber

Testing products from one temperature extreme to the other.

Workspace Range: 2 to 264 cu ft

Browse Thermal Shock Chambers >

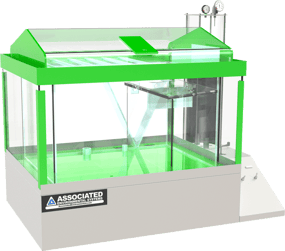

Salt Spray Chamber

Creates a corrosive environment without introducing other contaminants into the test area.

Workspace Range: 2 to 264 cu ft

Relevant Standards

Clients