Automotive

Environmental Test Chambers for the Automotive Industry

Ensure your vehicle components meet the highest standards of performance.

Ensuring vehicles meet stringent safety and reliability standards is a top priority for both automobile manufacturers and car parts manufacturers. AES environmental test chambers play a crucial role in this process by subjecting vehicles and components to rigorous testing in extreme conditions. From assessing quality and durability to verifying adherence to lifespan warranties, these chambers are indispensable tools in the automotive industry.

Environmental testing becomes even more critical for hybrid and electric vehicles reliant on lithium-ion batteries due to the batteries' sensitivity to factors like humidity. Our battery safety chambers and battery testing solutions are optimized to be able to help automotive manufacturers continue to test their products to be the best they can be.

Environmental Test Chambers are essential for testing individual components like seat belts, electronics, airbags, and engines and for conducting full vehicle testing, including vehicles as large as semi-trucks. With our extensive experience and commitment to innovation, AES remains the industry leader for automotive companies seeking reliable and cutting-edge testing solutions to meet the demands of the competitive market.

Test Chambers for Automotive: Talk to an Expert

Fill out the form, and you’ll soon be in touch with a test chamber expert.

Battery Testing for Electric Vehicles

Electric Vehicle (EV) Manufacturers rely on battery test chambers to simulate climates that EVs will often encounter on the road. Patented for a system for the high-density testing of batteries within an environmental test chamber, AES offers patented and patent-pending battery testing solutions that are equipped to grow alongside the fast-paced battery testing industries. We custom-tailor these fixtures specifically to your battery testing needs. Rest assured that AES is your innovation ally throughout your process and we are ready for the challenges of the road ahead.

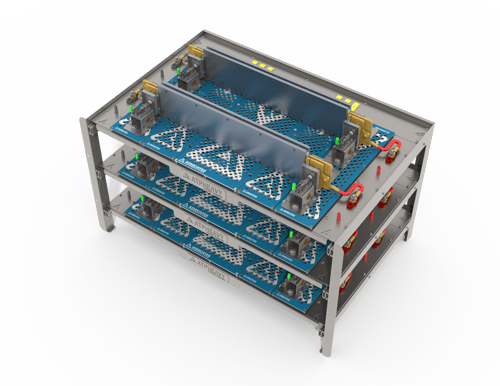

High Capacity Battery Testing

ATPHEAVY ADAPTABLE

The patent-pending ATPHEAVY ADAPTABLE is designed to accommodate larger capacity and higher current cells. The test surface allows for a modular design with interchangeable plates to support different cell sizes and current requirements of pouch, prismatic, and cylindrical cells. This solution will be custom molded to your cells, and be versatile incase of future shifts.

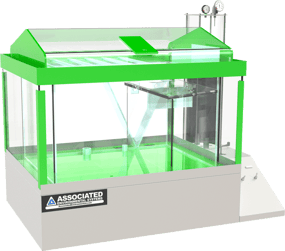

Integrated Battery Testing System

BATTERY TEST CHAMBER

Our battery testing fixtures seamlessly integrate within our battery safety chambers. Rated up to EUCAR Hazard level 7, our battery test chambers keep in mind operator safety. They are designed first to prevent and then mitigate in case of a battery thermal event.

ENVIRONMENTAL TEST CHAMBERS FOR AUTOMOTIVE

Battery Test Chamber

AES's battery testing chambers with added safety features to keep you safe

up to EUCAR 7 enable you to test nearly any battery cell type in controlled conditions.

Double stack options available.

Workspace Range: 8 and 12 cu ft.

Browse Battery Test Chambers >

Temperature Only Chambers

Conduct testing for precise temperature control and uniformity—benchtop, stackable, and walk-in room options.

Workspace Range: 2 to 264 cu ft

Browse Temperature Only Chambers >

Temperature & Humidity Chambers

Conduct temperature and humidity cycling testing. Benchtop, stackable, and walk-in room options

Workspace Range: 2 to 264 cu ft

Browse Temperature & Humidity Chambers >Thermal Shock Chamber

Testing products from one temperature extreme to the other.

Workspace Range: 2 to 264 cu ft

Browse Thermal Shock Chambers >

Salt Spray Chamber

Creates a corrosive environment without introducing other contaminants into the test area.

Workspace Range: 2 to 264 cu ft

-1.png?width=277&height=184&name=SD-508%20(2)-1.png)