Environmental Test Chamber

SD Series - Temperature Only

Request a Manual

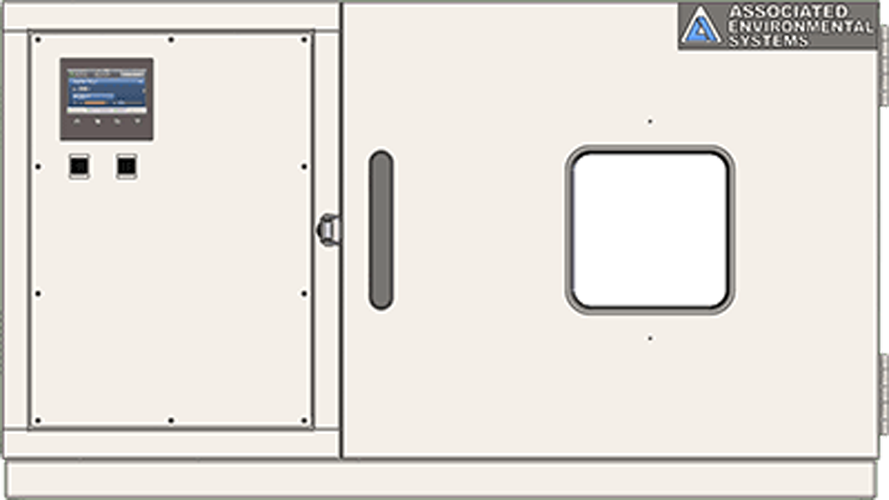

SD-501-ATP

Benchtop

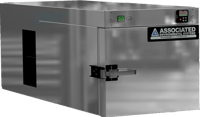

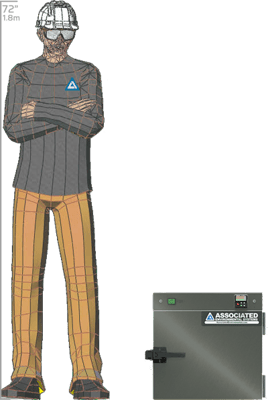

The SD-501-ATP Series is a unique benchtop environmental test chamber. The slim design takes up less space than any other chamber on the market today. It fits perfectly in a standard 19” rack. Specifically designed to hold smaller test units, this test chamber is engineered to meet the most demanding testing requirements across a wide range of industries.

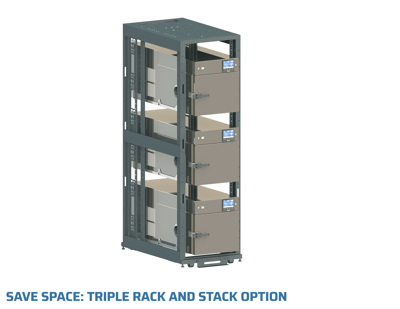

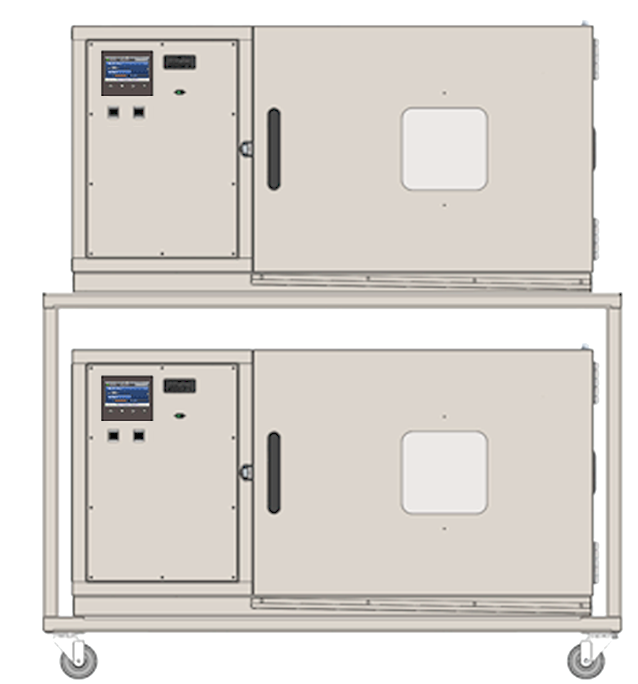

This benchtop test chamber is ideal for longer steady-state testing. Its unique slim style allows the chamber to be stacked one on top of the other in a server rack system allowing three independent tests to operate in the footprint of one test chamber.

STRUCTURE. Featuring polished, heavy-gauge, stainless steel construction, inside and out, makes the SD-501 Series Test Chambers ideal for dust-free, sterilized environments. Between the internal and external layers, is highly-efficient, low K factor, thermal insulation This test chamber is built to withstand constant use and efficiency.

The slim design of this test chamber allows for highly controlled test samples or small batch testing with nine channels spread over three shelves.

Three specialized ports allow for cable patches to feed through the back of the test chamber workspace and easily connect to your battery cycler test equipment.CIRCULATION SYSTEM. Air circulation is crucial for environmental testing. The SD-501 Test Chamber has a proprietary factory-adjustable baffle and fan design combination to optimize circulation conditions and temperature within the test workspace.

HEATING SYSTEM. Featuring industry-leading heating systems, SD-501 Series Test Chambers are equipped with multiple low-watt density, ceramic core, nichrome heaters for accurate temperatures within ±0.5°C, as measured at the sensor. The arrangement of the heater gives you ultimate temperature precision. If your testing requires conditions drier than the surrounding ambient air, add an optional dry air purge or dry nitrogen purge system.

INSTRUMENTATION. SD-501 Test Chamber incorporates AESONE CONNECT® creating a robust connected device giving you a standard and uniform interface that makes operation easier. Learn more in the Instrumentation Tab below.

- Specifications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

- Downloads

Specifications

SD Series

| Interior: | 13W x 13.5D x 9.9H (in) |

| 330.2W x 342.9D x 251.4H (mm) | |

| Exterior: | 18.8W x 46.7D x 18.8H (in) |

| 477.6W x 1186.2D x 477.6H (mm) | |

| Volume: | 1.01 cubic ft |

| 28.59 liters | |

| Temperature: | -37°C to 180°C (-34.6°F to 356°F) |

| Rise Rate*: | 2.8°C/min |

| Pull Down Rate*: | 3°C/min |

| Electrical Supply: | 120 VAC, 1 PH, 60 HZ |

| Full Load Amps: | 13 A |

| Facility Power Receptacle: |

NEMA 5-15

|

| Refrigeration System: | Single stage |

| Mobility: | Will fit through 32 in doorway |

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Notice for California Customers (SB1206):

For test chambers shipped to California, please consult our sales team regarding the use of R449A refrigerant (where applicable). This substitution ensures compliance with SB1206 regulations.

Standard Features

STANDARD FEATURES

- Temperature range -37°C to +180°C (-34.6°F to +356°F)

- External cabinet construction consists of 304 stainless steel

- Internal workspace constructed with type 304 stainless steel

- Full opening door with manual latch

- Interior light with exterior switch on cabinet face and operable on AESONE CONNECT®

- Port configuration: QT 3 rear wall access port and plug with 1in (25.4mm) diameter

- Fully adjustable shelf, 1 wire-grid shelf, stainless steel

- Forced air circulation

- Cable Leader, 10ft, 14 AWG, IEC-320-C13 to NEMA 5-15P

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

SD Series Test Chambers have incorporated AESONE CONNECT® creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE is hardware internal to the chamber that increases your functionality

- Connects the test chamber controller to your network for increased accessibility

- On-board multi-year data logging

AESONE SOFTWARE gives you the power to

- Remote chamber operation and monitoring,

- Web-based test profile creation,

- Viewing current data and historical data visually

- Secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS.

- TEMPERATURE SENSOR. Measured at the point of airflow entering the workspace. Class A, 3-wire, 100 Ohm Platinum RTD sensor

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

- HIGH/LOW-TEMPERATURE CONTROL. An adjustable temperature limit controller allows you to program the highest and lowest temperature of the device under test, protecting products from compromising temperature exposure.

- Refrigeration system over-pressure safety circuit

- TUV Rheinland certified meeting UL 61010-1, US, C, E

Optional Features

- Port Size/Access Point

- Additional Shelving

- Gas Purge compatible with Dry Nitrogen (GN2) & Compressed Dry Air (CDA)

- Stackable Rack Ability to Stack Three Units Vertically in a 19-inch Rack

- Made of Heavy-Duty Steel and Black Powder-Coat

- Compact Open-Frame Rack Design fits through Standard Height Commercial Doorways (in, cm)

- Leveling feet to ensure Optimal Performance on Uneven Floors

Downloads

Similar Products

Please Try Again.

.png?length=200&name=SD-501%20Per%20(1).png)