CONSUMER ELECTRONICS

Environmental Test Chambers for the Consumer Electronics Industry

Ensure the devices in your hand are built to last and meet the highest standards of reliability.

Consumer electronic device designers and manufacturers, including those producing smartphones, PDAs, and handheld/wearable electronic games, rely on AES environmental test chambers for comprehensive testing of devices, materials, internal components, and batteries. Given that most handheld devices are powered by lithium-ion batteries, which are highly sensitive to temperature, moisture, and humidity, stringent environmental testing is essential.

AES environmental test chambers simulate extreme hot and cold temperatures, humidity variations, and salt spray conditions to ensure consumer electronics' reliability and optimal performance. By subjecting new lithium-ion batteries to diverse simulated environmental conditions, these test chambers enable a broader range of chemical compositions to be evaluated in a shorter time frame. This reduction in testing time accelerates innovation, resulting in superior products for consumers.

Engineers can assess how batteries charge, discharge, and retain a charge under various real-world conditions. This rigorous testing is crucial for developing batteries that perform consistently and efficiently, regardless of the environment. This is why AES leads the industry with our battery testing solutions.

Test Chambers for Consumer Electronics: Talk to an Expert

Fill out the form, and you’ll soon be in touch with a test chamber expert.

Battery Testing for Consumer Electronics

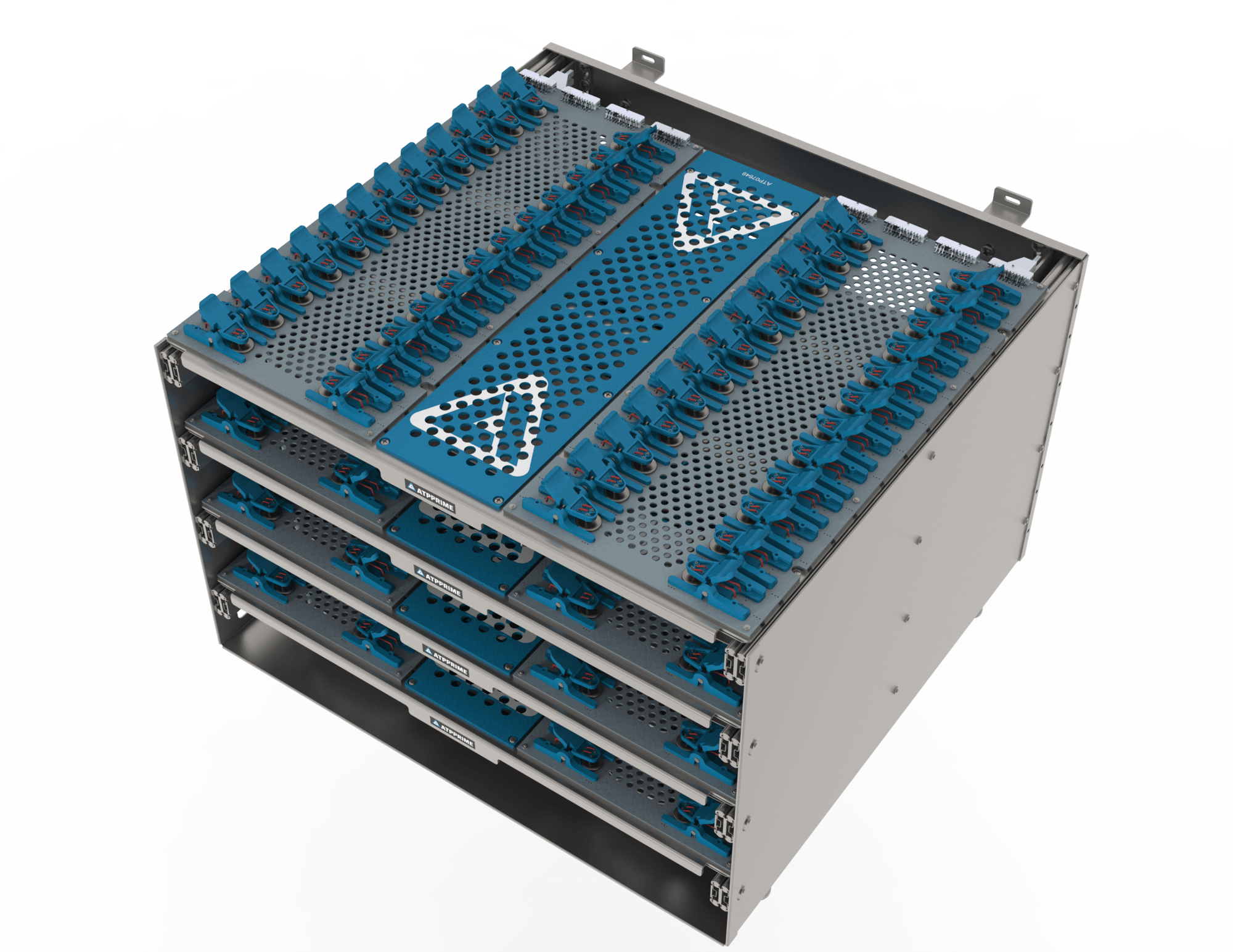

For over a decade, AES has been developing battery-testing solutions for the consumer electronics industry. Their offerings include ATPPRIME®, a patented system designed for high-density battery testing within an environmental test chamber. AES's solutions have expanded to support a wide range of cell formats, including prismatic, cylindrical, coin cells, and more.

Lower Current High-Density Testing

ATPPRIME

ATPPRIME allows for lower current high-volume testing. With solutions capable of testing up to 192 cells in one chamber, our ATPPRIME can maximize testing efficiency while keeping your testing safe and controlled. ATPPRIME can accommodate nearly all cell formats, including coin, cylindrical, prismatic, pouch, and pack cells.

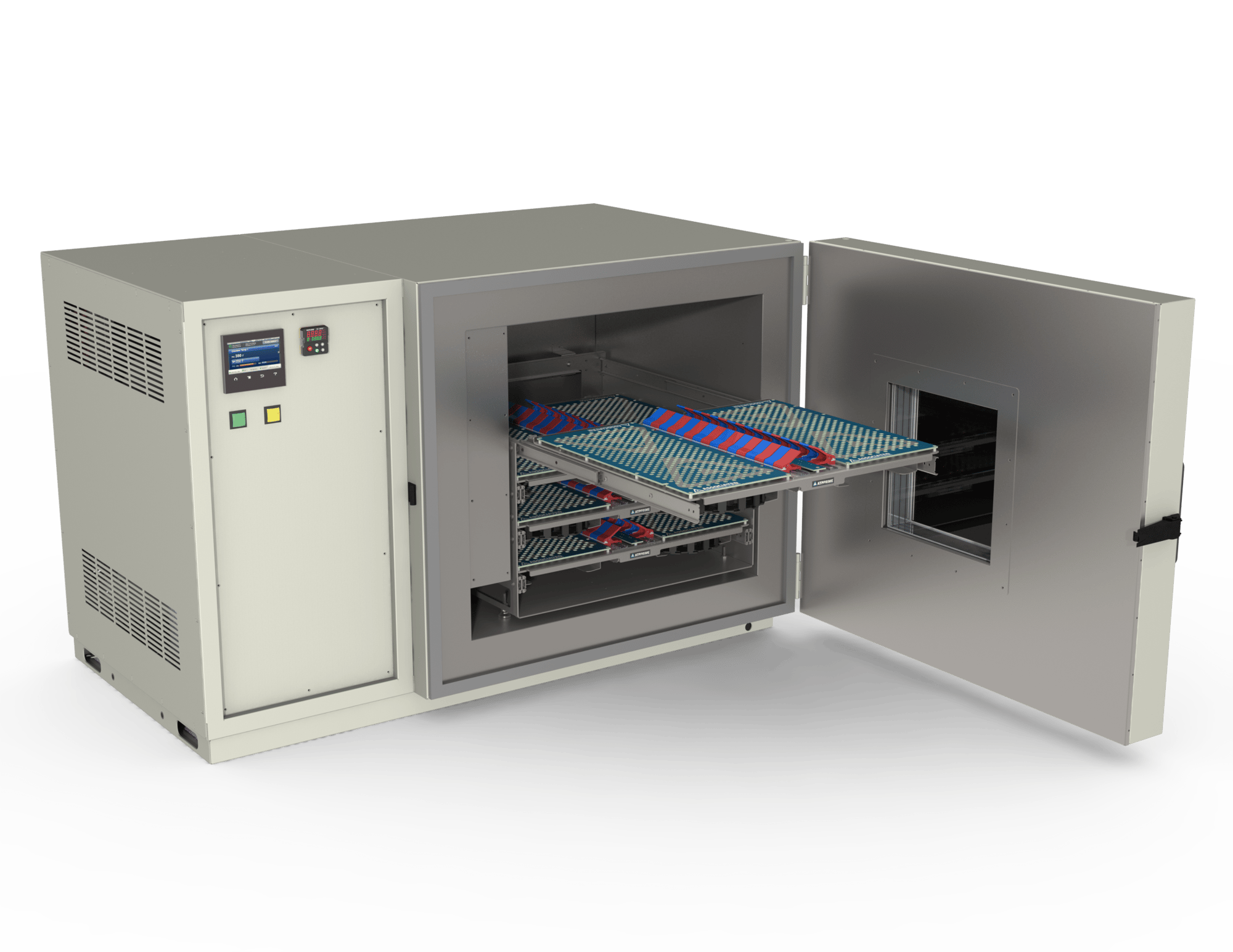

Integrated Battery Testing System

BATTERY TEST CHAMBER

ATPPRIME fully integrates with our battery safety test chambers. Equipped with safety features up to EUCAR level 7. Our safety chambers were designed first to prevent and then mitigate in the case of a battery thermal event (BTE).

RELEVANT ENVIRONMENTAL TEST CHAMBERS

Battery Test Chamber

AES's battery testing chambers with added safety features to keep you safe

up to EUCAR 7 enable you to test nearly any battery cell type in controlled conditions.

Double stack options available.

Workspace Range: 8 and 12 cu ft.

Browse Battery Test Chambers >

Temperature Only Chambers

Conduct testing for precise temperature control and uniformity—benchtop, stackable, and walk-in room options.

Workspace Range: 2 to 264 cu ft

Browse Temperature Only Chambers >

Temperature & Humidity Chambers

Conduct temperature and humidity cycling testing. Benchtop, stackable, and walk-in room options

Workspace Range: 2 to 264 cu ft

Browse Temperature & Humidity Chambers >Thermal Shock Chamber

Testing products from one temperature extreme to the other.

Workspace Range: 2 to 264 cu ft

Browse Thermal Shock Chambers >

Relevant Standards

Clients

-1.png?width=277&height=184&name=SD-508%20(2)-1.png)