Environmental Test Chambers For Humidity Testing

Humidity chambers are crucial for industries such as electronics, military and defense, pharmaceuticals, transportation, medical devices, shipping, and communications. Environmental test chambers for humidity testing enable industries to control temperature and humidity conditions precisely in an enclosed space. In doing so, you can test how products, materials, and components can be expected to perform in real-world environments.

Associated Environmental Systems (AES) is a trusted leader in the field. We offer various types of environmental test chambers, including temperature and humidity test chambers, that deliver high performance and precision to meet your testing process's demands. Our chambers are built to support your research, development, and testing needs with unmatched reliability.

What Is the Price of a Humidity Chamber?

The price of a humidity chamber varies depending on several factors, including size and performance. Small test chambers are less expensive than larger ones. The same is true for chambers designed for steady-state compared to cycling.

The more you need from your chamber regarding workspace volume, condition extremes, and change rates, the more you can expect to pay.

A good rule of thumb is that a quality, standard humidity chamber costs between $17,000 and $30,000. This base price often increases with customizations and optional features (such as dry air purges or recirculating desiccant air dryers). Work with a manufacturer to build a humidity chamber that fits your needs.

Industries That Rely on Humidity Chambers

Humidity chambers are essential for robust product development and validation in numerous industries. By enabling the simulation of diverse moisture conditions, these systems empower engineers and researchers to ensure performance, safety, and reliability. From evaluating sensitive components to guaranteeing material longevity, our chambers are built for your specific challenges.

Explore how humidity testing plays a role in each industry:

-

Electric Vehicles (EVs): Rigorous thermal stress testing to validate battery safety and performances.

-

Packaging: Comprehensive testing to guarantee your packaging effectively protects your product during transit and storage

-

Energy Storage: Evaluate cell and pack performance under varying environmental conditions.

-

Paints & Coating: Ensue the quality and longevity of your products.

-

Military & Defense: Meet strict military standards (MIL-STDs) with thermal testing.

Want to learn more about how we support each industry? Explore the industries we serve to see how our solutions align with your specific needs.

AES Humidity Chambers

AES offers the following series of temperature and humidity test chambers:

LH Series

The LH Series is available in benchtop or floor models, ideal for steady-state stability testing.

Temperature Range: -20°C to +94°C (-4°F to +201.2°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 1.3, 5, and 10 cu ft.

BHD Series

BHD series benchtop humidity chambers are stackable, enabling you to optimize lab space and test more efficiently.

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 2 and 8 cu ft.

SCH Series

The SCH Series features the most powerful benchtop chambers in the world. These humidity chambers are stackable, enabling you to optimize lab space and test more efficiently.

Temperature Range: -37°C to +180°C (-34.6°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 8 and 12 cu ft.

HD Series

HD floor models feature fast change rates to conduct high-performance testing and cycling.

Temperature Range: -70°C to +180°C (-94°F to +356°F).

Humidity Range: 10% to 95% (98% with added options).

Available Volumes: 2, 8, 10, 13, 18, 27, 36, 48, 64, 80, 96 cu ft.

Temperature Systems

Heating System

The heating systems in AES chambers are all-electric and pass air over fast-response, low-watt-density resistance heaters with a ceramic core, ensuring a long, reliable life with no downtime. The combination of airflow, instrument response, and these fast-reacting heaters give highly accurate and straight-line control of temperatures. These heating systems support temperatures upwards of 180°C (356°F), and heaters may be controlled independently or in unison. Heating systems are located in a plenum, so test items are not subject to direct radiation.

Standard temperature ranges: -37°C to +180°C (-34.6°F to 356°F) | -70°C to +180°C (-94°F to 356°F)

Precision: ±0.5°C

Cooling System

The cooling system in AES chambers consists of a self-contained mechanical refrigeration system with a single-stage or cascade configuration. You’ll have the option of air-cooling or water-cooling. Air-cooling comes with easier installation and is less expensive than water-cooling. However, it produces slower pulldown rates.

Water-cooling systems result in faster pulldown rates and are more energy efficient, but they require a dedicated, conditioned water supply and are more complicated to install.

You can supplement your system with boost cooling, employing liquid nitrogen (N2) or carbon dioxide (CO2) for even faster pull-down rates. It's a great option for stress tests that require rapid cooling. Even without boost cooling, AES standard cascade refrigeration systems have the fastest standard change rates of any environmental test chamber manufacturer.

Air Circulation

Air circulation is crucial for environmental chamber testing for humidity. AES’s chambers have proprietary baffle and fan design combinations that optimizes temperature conditions within the workspace.

Humidity System

AES uses vapor generator systems to give you precise control over the humidity conditions of your chambers’ internal workspaces. The vapor generator system is a closed stainless steel or copper tube. An element heats a constant water source creating vapor or steam that travels through the tube and mixes with conditioned air in a plenum before moving into the workspace. Notably, this water source must be treated and demineralized to avoid contaminating the test.

This system yields a standard relative humidity (RH) range between 10% and 98%.

Optional Features to Increase Humidity Range

High Humidity Sensors let you measure humidity as high as 98% RH.

Dry Air Purge Through Desiccant Air Dryers can achieve humidity as low as 5% RH. It compresses air through a desiccant system, absorbing the moisture before it moves into the workspace.

Dry Nitrogen Purges prevent condensation and frost from accumulating on DUT surfaces at colder temperatures by forcing out the moisture-heavy air. This also prevents the oxidation of metals at high temperatures.

Recirculating Desiccant Air Dryers are a more feasible option for larger chambers. Air is circulated through a desiccant system and then returned to the chamber, often cycled through a honeycomb wheel that releases captured moisture into the external workspace.

Associated Environmental Systems has developed a Dew Point Calculator to help you determine whether you'll need optional features for your humidity systems.

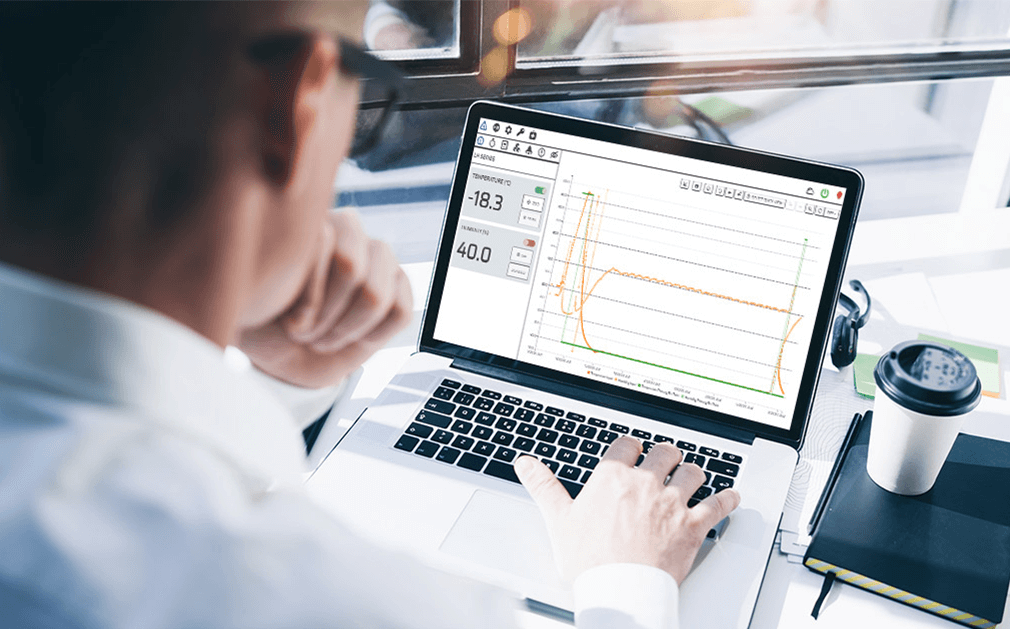

Remote Monitoring With AESONE CONNECT®

The days of standing next to your chambers to observe ongoing tests are over. AES humidity chambers come standard with AESONE CONNECT®, a combination of hardware and software solutions that enables you to monitor tests remotely. You can view real-time and historical data, create, edit, save, start, stop and move between test profiles from anywhere you can access a web browser.

Watching from a full-screen monitor, AESONE CONNECT® empowers you to design and rearrange tests with visually intuitive plot lines, clear data intervals, and colorful graphs. Furthermore, sharing a chamber is not a security problem. The administrator controls multiple login authentication methods and user-access permission levels and can establish expiration dates for each user.

If your budget can’t afford to purchase a new temperature and humidity chamber, AESONE technology can also be retrofitted to nearly any chamber you own. An AES team member will examine your configuration and retrofit the AESONE XCHANGE hardware to your chamber so you can connect to AESONE CONSOLE software.

Notably, well-cared-for chambers can function longer than ten years, outlasting their controller technology. Retrofits enable you to extend the lifespan of your chamber even further.

Humidity Chamber Maintenance

Regular environmental test chamber maintenance keeps your chambers running for 10 years or more, and it’s crucial, in particular, for humidity chambers. These test chambers require properly conditioned water. AES suggests defined ranges for resistivity of (0.05MΩ * cm to 6MΩ * cm, conductivity, 20µS to 0.167µS TDS: 10 ppm to 1 ppm, and total dissolved solids (TDS) (10 ppm to 1 ppm). The demineralizing cartridges used to condition the water should be checked monthly.

In addition, be aware of any buildup of sediments and sitting water, which can lead to mold or mildew that corrodes metal over time. Don’t worry, though; AES has expert service techs around the country who are ready to ensure your humidity chambers retain their top performance.

Humidity Chamber Resources & FAQS

How does a humidity chamber work?

Leading test chamber manufacturers build humidity chambers with closed vapor generator systems. They require properly conditioned water as well as regular maintenance to ensure performance. Read more on How Humidity Chambers Work.What are the leading functions of a humidity chamber?

Humidity chambers rely on vapor generator systems to create specified conditions in the workspace. Companies across industries (from packaging to electronics, pharma, communications, and more) test their products in humidity to evaluate the effectiveness of those products in different environmental conditions and set expectations for consumers. Read more on Test Chamber Functions.Humidity chambers: Calculating dew point to fit your testing

The relationship between temperature, relative humidity, and dew point can be a bit complicated to calculate, but it’s vital for ensuring reliable and consistent humidity testing. Read more on Calculating Dew Point.

Common Humidity Chamber Questions

Request More Info

Associated Environmental Systems is committed to long-term, responsive relationships with our customers. Looking to purchase a new chamber? Have questions about service, support, or retrofitting an existing chamber?

Don't hesitate to contact us with your questions or challenges.

.png?width=326&height=252&name=SD-508%20(2).png)