Walk-in Series - Temperature with Humidity

Request a Manual

WRH-STRUCTURAL

FloorWalk-In

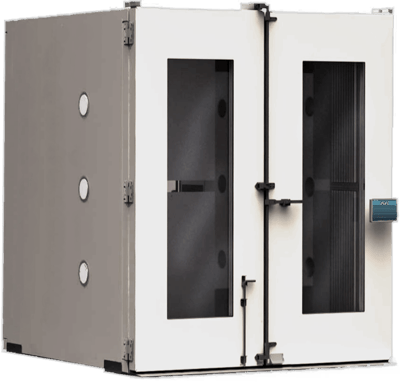

Solid-structure walk-in models are built using AES' high-performance versions of the popular floor-style models and can be ordered for stability testing purposes or cycle testing.

STRUCTURE. When you require extreme temperatures and saturated humidity rates, your testing is more suited to structural build construction. Structural walk-in rooms are welded, one-piece units assembled with durable steel making them optimal for heavy or over-sized product loading and high humidity. Structural walk-in rooms are advantageous for speedy temperature change rates, high humidity, and explosion resistant applications.

In high-humidity conditions where increased pressure is present, a welded-steel structural frame interior is required. Under these reinforced conditions, temperatures from -65°C to +150°C (-85°F to +302°F) can be sustained. And relative humidity can range from 10-95%.

Structural build chambers are most often custom-designed products. Because of our extensive product offering and years of designing test chambers, your specific needs will not increase delivery time, but they do require more planning and engineering design time to create the plans and drawings which are followed by customer approvals before manufacturing can begin.

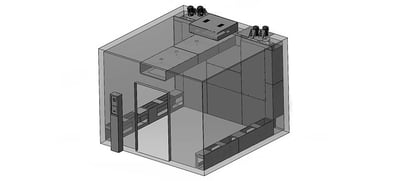

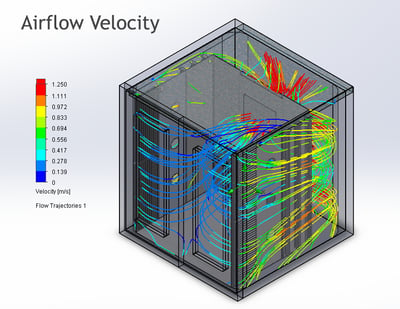

PERFORMANCE. To optimize temperature conditions within the workspace a specially designed plenum allows airflow to enter the space from the back and pushed to the sides for conditioning. Toward the front of the workspace, registers spread the air top to bottom creating a uniform workspace for testing dense products under dead-load and live-load situations.

Airflow for products under test is fed by triple-blower wheels at the back wall with left and right air discharge. Plenums on both the left and right sides condition and discharge air to the front of the workspace through baffles that direct the airflow uniformly top to bottom. As air enters through the back of the chamber, the flow is directed along the sides through a plenum where the air is conditioned to the correct temperature. When the air reaches the front of the chamber it flows through registers with baffles that direct the air to move uniformly from top to bottom. Stacked circulation fans on the back wall of the workspace pulls the air through the product and back into the plenum to be reconditioned.

Access ports can be placed on each side, using your specific requirements.

HEATING SYSTEM. A mix of several open nichrome heaters and ceramic core nichrome heaters spread across airflow for reliable and accurate temperature control within ±0.5°C.

HUMIDITY SYSTEM. Reach highly saturated humidity levels with no concerns. High-pressure environments require solid structures so there is no chance of leakage through seams. To extend your humidity range, see the optional features section. View RH Chart.

COOLING SYSTEM. The cooling system is a self-contained mechanical refrigeration system with the configuration that will fit your needs. An AES engineer can discuss the benefits of a water-cooled or air-cooled condenser.

Add boost cooling with liquid LN2 or CO2 for even faster pull-down rates. It's a great option for stress tests that require rapid cooling. Even without boost cooling, AES’ standard cascade refrigeration systems have the fastest standard change rates of any environmental test chamber manufacturer. See Basic Specifications tab below.

INSTRUMENTATION. Walk in Series Test Chambers have incorporated the AESONE CONNECT® creating a robust connected device for a standard and uniform interface making operation easier.

- Applications

- Standard Features

- Instrumentation

- Safety Features

- Optional Features

Applications

STABILITY WALK-IN CHAMBERS

When products need to be tested or stored in a constant environment, stability chambers will replicate such conditions.

Stability chambers are meant to run constantly for long periods of time at a consistent temperature with or without humidity.

These steady-state chambers are electronically configured to meet several governmental regulations and test requirements in industries such as electronics, healthcare, food and beverage, packaging, life science, and more. Chambers are always factory set and configured to meet your specific test requirements, and a service team member can calibrate the chamber to ensure accuracy.

Below are common sizes manufactured at Associated Environmental Systems in Acton, Massachusetts. We are known for building custom stability chambers which meet our customers specifications with the same manufacturing lead times as standard chambers.

Common Standard Sizes

| Working Volume † | Exterior † |

|---|---|

| 264.8 cu ft (7,498.3 l) Interior: 52x88x100 in | 60x96x116 in |

| 337.9 cu ft (9,568 l) Interior: 52x112x100 in | 60x120x116 in |

| 485.1 cu ft (13,736 l) Interior: 88x88x108 in | 96x96x124 in |

| 617.4 cu ft (17,482.8 l) Interior: 88x112x108 in | 96x120x124 in |

| 785.8 cu ft (22,251.4 l) Interior: 112x112x108 in | 120x120x124 in |

| 954.2 cu ft (27,019 l) Interior: 136x112x108 in | 144x120x124 in |

| 1,112.6 cu ft (31,788.5 l) Interior: 160x112x108 in | 168x120x124 in |

Stability Performance

| Temperature Only* or Temperature & Humidity* | ||

|---|---|---|

| Standard Range -40° C to +85° C | Extended Cold Range -65° C to + 85° C | Extended Hot Range -40° C to +150° C |

| Standard: 3.5HP, Air Cooled Unit Optional: Water Cooled Unit | ||

| Specify your needs, and an Associated Environmental Systems Engineer will work with you to calculate your needs for temperature system or a dual temperature and humidity system. The gray ranges in the chart are the most common. However, other configurations are available. | ||

* Temperature and humidity at sensor † Additional WidthxDepthxHeight configurations available

*Rise and pull-down rates calculated using IEC 60068-3-5 standard. Custom options available.

*Ideal ambient temperature conditions for test chambers is 23°C (73.4°F). The temperature and humidity range of assured performance is between 15°C and 25°C (59°F/77°F) and 30-50% relative humidity. Conditions outside this range may affect the performance of your test chamber and reduce the lifespan of the equipment.

Standard Features

- Temperature Range: -65°C to 150°C ( -85°F to 302°F)

- Interior Cabinet: stainless steel, Type 304

- Exterior Cabinet: cold rolled steel, heavy-gauge, powder coat finish, color: bone

- Port Configuration, 2 back panel, stainless steel ports, with 4in (101.6mm) Diameter

- Internal Light with External Switch Full Opening Bi-parting Doors, Manual Door Latch,

- 2 Full-Length, Multi-Pane Viewing Window

- Forced Air Circulation

Instrumentation

STANDARD INSTRUMENTATION

CONTROLLER

Walk-in Series Test Chambers have incorporated AESONE CONNECT® creating a robust connected device for a standard and uniform interface making test chamber operation easier.

AESONE XCHANGE increases your functionality

- connects the test chamber controller to your network for increased accessibility

- on-board multi-year data logging

AESONE SOFTWARE gives you the power to

- remote chamber operation and monitoring,

- web-based test profile creation,

- viewing current data and historical data visually

- secure multi-level user access

ADDITIONAL ONBOARD INSTRUMENTATION

WATLOW F4T PROGRAMMABLE CONTROLLER. Features a 4.3” capacitive touchscreen minimizing the chance for error. Ethernet communication supported by AESONE HARDWARE. View more controller options

SENSORS.

for humidity, solid-state sensor for 10-95% relative humidity

OPTIONAL DATA LOGGERS. View additional data loggers

Safety Features

STANDARD SAFETY FEATURES

- HIGH/LOW TEMPERATURE CONTROL. an adjustable temperature limit controller allows you to program the highest and lowest temperature of the device under test, protecting products from compromising temperature exposure.

- Internal high-temperature limit safety

- Refrigeration system over-pressure safety circuit

- TUV Rheinland Certified Meeting UL 508A, US, C, E

Optional Features

- LN2 Boost Cool

- CO2 Boost Cool

- Adjustable Saftey with Alarm

- Honeywell Chart Recorder

- Honeywell Digital Chart Recorder

- Change Port Size/Access Point

- Desiccant Air Dryer to ensure conditions as low as 5% RH

- Dry Nitrogen Purge to keep condensation and frost from accumulating on DUT surfaces at cold temperatures and to prevent oxidation of metals surfaces at high temperatures

- Dehumidifier

- Water-Cooled Condenser

- Noise Reduction Package

- Alternative Power Requirements

- Other Options Available on Request

Similar Products

Please Try Again.