eVTOL

Environmental Test Chambers for the eVTOL Industry

Make Sure Your eVTOL Components Are Ready for the Skies.

As the eVTOL (electric vertical takeoff and landing) industry continues to push the boundaries of urban air mobility, ensuring these aircraft's safety, reliability, and efficiency is critical. AES environmental test chambers play a vital role in this process, subjecting eVTOL components and systems to extreme environmental conditions to validate their performance, longevity, and compliance with rigorous aviation standards.

eVTOL aircraft rely heavily on high-performance lithium-ion batteries, advanced electronics, and lightweight composite materials—all of which are highly sensitive to temperature fluctuations, humidity, and other environmental stressors. Our battery test chambers and battery safety solutions are specifically designed to simulate real-world conditions, helping manufacturers optimize battery performance, enhance safety, and mitigate risks such as thermal runaway.

Beyond batteries, environmental testing is essential for evaluating critical components such as propulsion systems, avionics, sensors, and structural integrity under diverse conditions, including rapid temperature shifts, high altitudes, and humidity exposure. With our extensive experience in aerospace and battery testing, AES provides cutting-edge solutions to help eVTOL manufacturers meet the demands of this rapidly evolving industry.

Test Chambers for eVTOL: Talk to an Expert

Fill out the form, and you’ll soon be in touch with a test chamber expert.

Battery Testing for eVTOL

eVTOL manufacturers rely on advanced battery test chambers to simulate the extreme climates these aircraft may encounter in flight. Patented for high-density battery testing within environmental chambers, AES offers innovative, patent, and patent-pending solutions designed to evolve with the rapidly advancing eVTOL industry. Our custom-tailored fixtures are specifically built to meet your unique battery testing needs. With AES as your trusted innovation partner, we’re ready to help you navigate the challenges of the skies ahead.

High Capacity Battery Testing

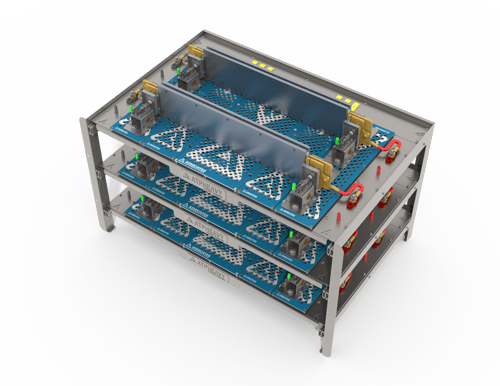

ATPHEAVY ADAPTABLE

The patent-pending ATPHEAVY ADAPTABLE is designed to accommodate larger capacity and higher current cells. The test surface allows for a modular design with interchangeable plates to support different cell sizes and current requirements of pouch, prismatic, and cylindrical cells. This solution will be custom molded to your cells, and be versatile incase of future shifts.

Integrated Battery Testing System

BATTERY TEST CHAMBER

Our battery testing fixtures seamlessly integrate within our battery safety chambers. Rated up to EUCAR Hazard level 7, our battery test chambers keep in mind operator safety. They are designed first to prevent and then mitigate in case of a battery thermal event.

RELEVANT ENVIRONMENTAL TEST CHAMBERS

Battery Test Chamber

AES's battery testing chambers with added safety features to keep you safe

up to EUCAR 7 enable you to test nearly any battery cell type in controlled conditions.

Double stack options available.

Workspace Range: 8 and 12 cu ft.

Browse Battery Test Chambers >

Temperature Only Chambers

Conduct testing for precise temperature control and uniformity—benchtop, stackable, and walk-in room options.

Workspace Range: 2 to 264 cu ft

Browse Temperature Only Chambers >

Temperature & Humidity Chambers

Conduct temperature and humidity cycling testing. Benchtop, stackable, and walk-in room options

Workspace Range: 2 to 264 cu ft

Browse Temperature & Humidity Chambers >Thermal Shock Chamber

Testing products from one temperature extreme to the other.

Workspace Range: 2 to 264 cu ft

Browse Thermal Shock Chambers >

Relevant Standards

Clients

-1.png?width=277&height=184&name=SD-508%20(2)-1.png)