Electronics That Sweat

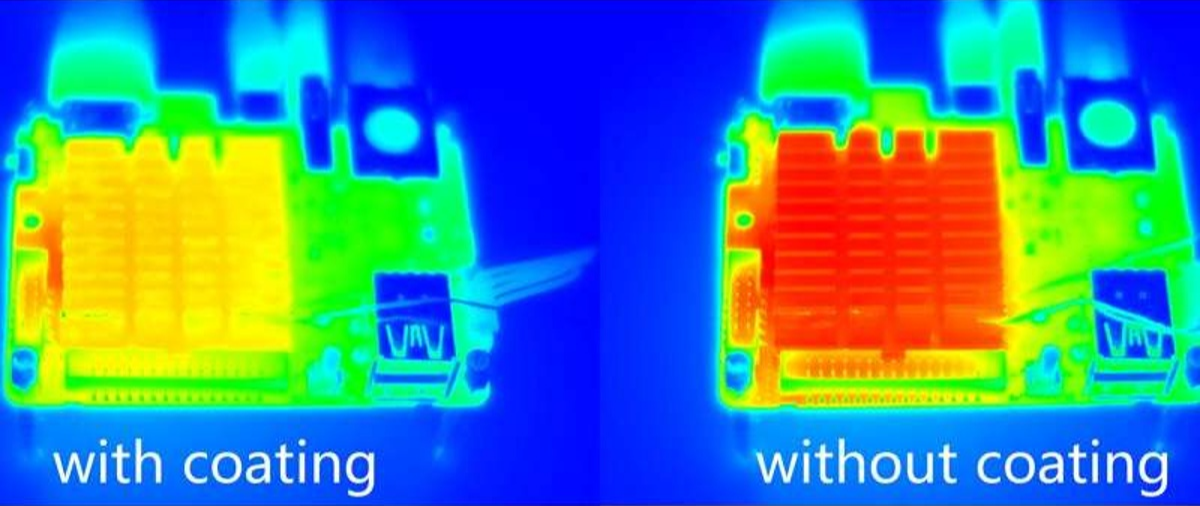

Researchers at Shanghai Jiao Tong University in China are working to develop a coating for electronics that releases water vapor to dissipate heat from running devices. This new temperature regulating system could help to prevent electronics from overheating and may even be more efficient than some current thermal management methods.

Researchers at Shanghai Jiao Tong University in China are working to develop a coating for electronics that releases water vapor to dissipate heat from running devices. This new temperature regulating system could help to prevent electronics from overheating and may even be more efficient than some current thermal management methods.

Refrigeration engineering student, Ruzhu Wang, explains, “The development of microelectronics puts great demands on efficient thermal management techniques, because all the components are tightly packed and chips can get really hot...For example, without an effective cooling system, our phones could have a system breakdown and burn our hands if we run them for a long time or load a big application.”

Current thermal management systems typically use waxes or fatty acids called Phase Change Materials (PCMs) to regulate temperature. These materials keep electronic devices cool by absorbing heat as they melt. In contrast, Wang and his colleagues are studying porous materials that can absorb moisture from the air and release water vapor when heated.

The team is particularly interested in the properties of metal organic frameworks (MOFs), which were originally considered for extracting water from desert air. MOF coatings have a lot of potential for electronics cooling because they are able to store relatively large amounts of moisture and more water equals more cooling.

According to a recent Physics.org article, “The team found that the coating was able to delay the temperature rise of the sheets, and the effect increased with coating thickness. While an uncoated sheet reached 60°C after 5.2 minutes, the thinnest coating doubled the time and didn't reach the same temperature until 11.7 minutes. The sheet with the thickest coating reached 60°C after 19.35 minutes of heating.”

Importantly, the coating is able to quickly reabsorb moisture as it cools, allowing the process to happen repeatedly - a similar process to a mammal hydrating and sweating.

Initial testing is promising but there is still much work to be done in developing this technology. Temperature and humidity chambers will almost certainly play a crucial role in that development because researchers will need to tightly control and monitor conditions of coated materials.

Associated Environmental Systems temperature and humidity chambers are designed to maintain precisely controlled environmental conditions. We have developed innovative rackmount systems which allow our clients to test and monitor electronics under load and we can even create custom temperature chambers for special applications. We have the experience and know-how and we have worked with many of the leading electronics manufactures on innovative projects like this.

For more information about Associated Environmental Systems environmental chambers, click HERE. You can also contact one of our expert representatives by clicking HERE or click the chat-box to the right of this page.

Share: ![]()

![]()

![]()