Building vs Buying a Battery Test Chamber

As sources of power, batteries function as the unseen heroes for some of the world’s most advanced technology. If they fail, the product itself fails. Luckily for consumers, batteries go through rigorous testing in research and development (R&D) and production phases before they ever hit the market. Quality assurance only works, though, if you can guarantee the process.

That’s more of a gamble for companies that choose to build their own battery testing environments. Each stage brings its own variables, with one error enough to disrupt the product’s timeline. That might not be a big deal for short-run testing, but for larger tests, it could prove catastrophic.

Modern battery test chambers, on the other hand, have been optimized for load sizes, efficiency, and accuracy, ensuring a strong return-on-investment. They’re designed with lean manufacturing in mind, a methodology that minimizes waste—defined as anything customers believe adds little to no value—and maximizes productivity.

Factor in customization and flexibility options, and you can bet a test chamber exists, or can be built, to fit your budget and testing requirements.

Here’s what you need to know about building your own battery test chamber versus buying one.

Building Your Own Battery Test Chamber

The benefits of building your own battery test environments depend on your risk management, because they’re neither lean nor safe.

If you searched for existing models of this type, you’d likely see rudimentary tools: cable ties, electrical tape, various clips, and cardboard. Passable setups involve wire crossings and potential issues before the tests even begin.

The circumstances for building and running a battery test environment have to be just right.

It starts with your team. If you have experienced engineers on staff, you could probably get by. They can find the resources necessary and devise a setup that works for limited testing, but they’ll need a thorough understanding of lithium-ion batteries and how they interact with test chambers. Your team must understand the appropriate materials to use—for example, choosing non-conductive over conductive metals—adequate airflow measures, and how to organize the different components.

Another factor is your testing needs. Battery development and early battery prototyping require sensitive, expensive equipment because you’re experimenting with chemical components. It’s a much more complex process than simply testing the batteries—by repeatedly charging and discharging hundreds or thousands of cells in a series.

Yet the latter scenario doesn’t mean building your own test chamber is the right solution. There are risks at every step, from design to testing. If even one organizational piece falls through, the defect can throw off your entire process.

The most extreme case is an explosion. It’s rare, but a possibility. A more common occurrence would be short-circuiting, which could trip the cycler for individual channels. Resetting everything takes time and expertise to ensure a second attempt doesn’t meet the same fate as the first. You’d also have to qualify existing data (if it wasn’t lost) or dismiss it as inaccurate.

Even if everything goes to plan, there’s a lack of repeatability. Different load sizes require different configurations.

For smaller, limited tests, it might make financial sense to build your own battery test environment. For all others, the time and effort to ensure accurate results outweigh the one-time cost of purchasing a battery test chamber. When you factor in the ease of use, it’s a no-brainer.

Buying a Battery Test Chamber

When you purchase a battery testing solution, you limit risk, ensure accuracy, and gain so much more: peace of mind and efficiency.

The time-saving costs alone make it budget friendly, although there’s still flexibility. Associated Environmental Systems (AES) offers three distinct battery testing environments: The All Test Platform Prime (ATPPRIME) model is a full test chamber. The ATPFLEX, on the other hand, can be added to your current environmental test chamber while providing many of the same great benefits. ATPHEAVY enables testing of batteries up to 1000 AMPs per cell, crucial to developing EV batteries.

The advantages of purchasing ATPCHAMBERS include the following:

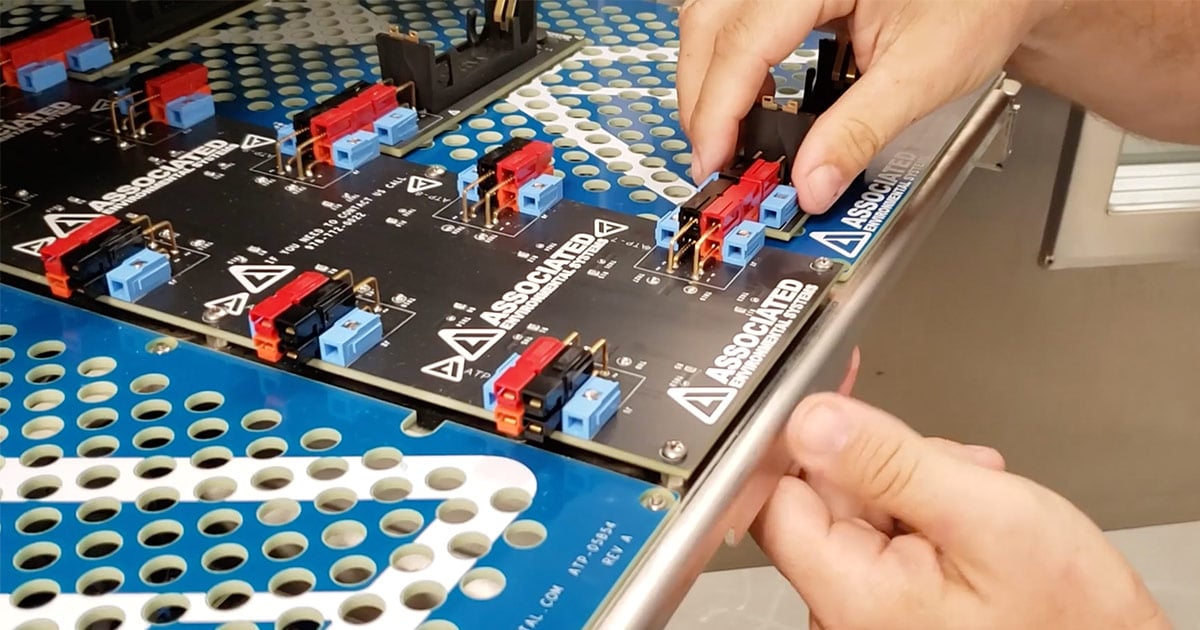

- Everything is clearly labeled to reduce your setup time and get you testing safely sooner.

- Test almost any battery cell type: coin, cylindrical, prismatic, pouch, and pack cells.

- The built-in Battery Interface Board (BIB) manages the data collection system for charge and discharge measurements, ensuring accurate sensor readings.

- Remotely monitor and operate the environmental test chamber and battery cycler from one control panel for synchronous operational activity, and collect correlated temperature and cycling data in one location.

- Safety features include a nitrogen purge, an inert gas pressure vent, a ventilation blower, and more.

Then there are the customization possibilities. Each test chamber can be modified to fit your needs, and the configuration functionality enables you to switch out as many as 48 cells in five minutes.

That efficiency translates to more accurate tests in a shorter amount of time, a result that fits into any budget.

Plus, with the ability to test almost any battery type, including those with a high amperage (up to 1000 amps), such as those used in electric vehicles, ATP chambers provide flexibility able to accommodate cutting-edge innovations in battery technology.

A reliable manufacturer will include test chamber support and maintenance throughout the operational lifetime, including scheduled repairs. Maintenance is a short-term cost that reaps long-term benefits.

Ultimately, when you buy a battery test chamber, you transfer responsibility from your engineers to our experts, so your team can focus on what they do best—delivering a product that delights your customers.

Whether it’s a brand new ATPPRIME or ATPFLEX addition for an existing environmental chamber, Associated Environmental Systems has the expertise and experience to find a working battery testing solution for you. Contact us today.