What Are The Safety Hazards of Batteries?

Battery Hazards

As batteries become increasingly more important in future technology, companies must prioritize how to properly handle them and ensure that they are manufactured according to safety guidelines. While your typical AA battery might seem harmless from the outside, the reality is that batteries are entities that contain a strong concentration of energy that must be both stable and predictable. If there is a structural issue or energy does not cycle properly, serious safety hazards leave company employees and consumers vulnerable to vicious side effects. In this article, we will outline what these battery hazards look like, how you can prevent them, and how AES can help you with testing batteries.

What are the Different Types of Battery Hazards?

Reliability of batteries has emerged as one of the top issues in many industries that have seen technological advancements in the past few decades. A US FDA survey, for example, stated that "up to 50 percent of service calls in hospitals surveyed relate to battery issues," and professionals at AAMI have concluded that "battery management has emerged as a top 10 medical device challenge." Furthermore, in the military industry, the service duration on a battery's date stamp is often limited to 2 to 3 years to cover all eventualities. Examples like this demonstrate that extra precautions are taken in order to make sure that batteries are working properly and, most importantly, are safe for the user. The following is a list of battery is issues that can manifest in a dangerous way:

Short-Circuiting

If the electrical current in a battery is released in an uncontrolled manner or the current passes through a conductor with too low of a resistance, a large amount of energy will be delivered in a short period of time. This sudden surge of energy can transform into a strong electrical explosion (arc flash), intense heat, or even fires that cause a hazard for everyone around it.

Battery Acid

Aqueous sulfuric acid is a fundamental component of a battery's functionality, as it acts as the medium that carries electrical flow between positive and negative electrodes. Sulfuric acid alone, however, is an extremely corrosive substance that can eat through surfaces & clothing, and it can burn through skin and eyes when in human contact. Therefore, any of these solutions not properly stored in the battery can serve as a risk to anyone handling the battery or even in the near vicinity.

Flammable Gasses

Some batteries emit hydrogen gas during charge and discharge cycles due to the reaction between water and sulfuric acid. Hydrogen gas ignites very easily and can cause explosions and/or fires if the levels of H2 are not monitored properly or the room in question does not have proper ventilation.

Battery Burst: Any combination of excessive charging, short-circuits, and build-up of gas within the battery can cause it to suddenly burst, which can lead to chemical burns and shrapnel injuries.

Weight

While many of the dangers/hazards associated with batteries can be attributed to their internal mechanics and chemistry, a potential danger that many overlook is the battery apparatus itself. Batteries used in large industrial applications can weigh up to 100+ lbs per cell, and that does not even take into account the massive battery banks that they rest on, which collectively can add up to more than 1000 lbs. If corrosive durability or structural integrity is not properly tested, the sheer weight of the batteries in question can pose a threat to those around the system.

Minimizing Battery-Related Damages in the Workplace

With these risks in mind, it is important that a company primes its workspace with optimal conditions and readily-available safety equipment in case of an emergency. The latter includes personal protective equipment such as goggles, face shields, rubber gloves, and rubber aprons as well as last resort protective equipment such as fire extinguishers, emergency showers and eyewash stations, and first-aid kits. When it comes to the workplace itself, make sure that the room in question provides adequate ventilation to disperse fumes given off during charging and have built-in safety features such as sprinklers in case of a fire-related event. While it is rare that your battery will fail or even form as a danger to those around it, setting up a system to mitigate that risk is key to ensuring a safe working environment for all employees.

How AES Can Help Prevent Battery Hazards

While a company may be ready in case of emergency when manufacturing a battery on site, this risk is simply out of their control once that battery is distributed and in the hands of consumers. This is where AES comes into the equation.

Battery Testing Methods

Associated Environmental Systems acknowledges that leading-edge battery technology requires leading-edge testing solutions, and we have developed state of the art battery testing chambers designed to assess your products under a wide range of temperatures, temperature fluctuations, and humidity rates. Any performance fault or safety hazard can be caught before mass production, and catching these issues beforehand can save companies a considerable amount of time, money, and resources. This testing technology is also beneficial for the consumer, as it optimizes the useful life of the product and ensures safety even under the most extreme conditions.

AES also provides well-designed battery testing fixtures meant to supplement the experience of using a battery testing chamber by limiting waste, maximizing efficiency, and allowing users to safely swap in battery cells without jeopardizing testing results. These products are known as AES' ATP Series, which includes ATPPRIME, ATPHEAVY, and ATPFLEX (learn the differences here). The ATP surface itself is heat- and fire-resistant to help minimize the effect of the cell shorting, and each channel is spread apart and labeled to lower the risk of one cell propagating to another.

Battery Testing Safety

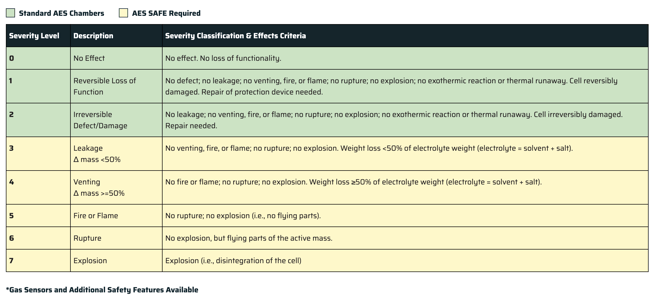

Associated Environmental Systems has launched our battery test chambers with built-in battery safety features known as AES SAFE. Built upon EUCAR Hazard Levels, our battery test chambers are designed to create a safer testing environment for your products, battery testing lab, employees, and equipment. These safety features are built around minimizing the damage in case of a thermal event; the hazard level is in place to help assess and predict possible dangers associated with battery testing. With the capabilities of AES SAFE, chambers are equipped with the necessary safety features that can protect up to hazard level 7 which are described in detail below:

To mitigate these potential battery hazards, AES SAFE includes the following safety features:

- Emergency Stop: This button enables you to disrupt the entire function of the reach-in test chamber rapidly

- Set Point Temperature Limit: A temperature control feature prevents a user from unintentionally setting temperatures beyond the established testing limits.

- High/Low-Temperature Limit: Operates independently of the set point temperature limit, ensuring the control temperature limit doesn't exceed what is safe for cells.

- Audible & Visual Alarm: A loud sound is emitted when an emergency condition is in play, while a visual cue will reveal the state of the chamber.

- Color guide:

- Green indicates the chamber is ready for use, and the door is unlocked.

- Blue indicates the chamber is in use, and the door is locked.

- Red indicates the chamber is in alarm condition and the door is locked.

- Rapid Temperature Change: A safety feature in place to monitor and detect when a rapid temperature shift occurs.

- Temperature Limited Sheath Heaters: The stainless steel, finned tubular hearts with a temperature sensor limit the maximum operating temperature of your battery test chamber.

- Reinforcement: A reinforcement stainless steel interior provides the durability necessary to conduct high-stakes battery testing.

- Chamber Alarm Input: When the external Terminal block voltage signal is disrupted this feature triggers an alarm state and the entire chamber shuts down

- Chamber Alarm Output: This feature is intended to safely disable test equipment for a device under test and communicate with your battery cycler.

- Door Lock: Not only should your chamber have a fail-safe rotary cam door to ensure it locks, but a mechanical override in case some electrical components malfunction. A cam position sensor indicates whether the door is locked. Most chambers will not function with an open or unlocked door.

- Safety Purge: When the reach-in test chamber is in an alarm state, this device triggers an inert gas purge in order to remove toxic gasses from the enclosed environment.

- Burst Disk/Low Flow Vent: Made from Graphite, this burst disk contains rupture sensors that trigger your alarm system.

- Product Sensors: Installed on the rear of the chamber, these sensors enable you to monitor the products under test

- Gas Sensors (optional): Sensors that monitor the chamber for combustible gasses.

Conclusion:

Batteries are the main focus of most if not all emerging industries as of late. Truly understanding their composition, limitations, and vast capabilities, however, takes a comprehensive understanding as well as innovative technology. AES is a leading test chamber manufacturer that can help provide companies with their battery testing needs and ensure that their products provide maximum performance and minimized risk with the utmost confidence.

Contact AES to speak with a battery testing expert:

sales@associatedenvironmentalsystems.com or call 978-772-0022