Struggling with an AES environmental test chamber that is failing to heat properly? This guide walks you through common issues, troubleshooting steps, and solutions to get your chamber back up and running efficiently.

After entering my setpoint my chamber fails to heat up. Where should I begin troubleshooting?

As an initial step, you will want to check the controller to make sure it’s initiating the call for heating. An F4T controller programmed for heating should look like the picture attached below; the control mode (displayed above the setpoint in the top right) should be set to Auto and a percentage should be displayed in the output PWR bar for heating (this will be the PWR bar on the left side of the screen . You can change the control mode if needed by pressing the three white dots in the top right. You will also want to make sure that the event needed to trigger heating at the bottom of the controller (usually labeled either “Heat” or “Conditioning Enabled”) is selected.

The picture above is from a temperature-only chamber. A humidity chamber will have two different blocks on this screen, the one for temperature will be the one on the left.

The picture above is from a temperature-only chamber. A humidity chamber will have two different blocks on this screen, the one for temperature will be the one on the left.

On F4 controllers, the output for heating is the light next to the controller screen marked 1A; this should be illuminated if the controller is set to raise the chamber’s temperature.

My controller is displaying all the correct settings for heating. What next?

Check the limit controller to make sure that’s not preventing the chamber from heating. If your chamber has a Watlow EZ-Zone PM Limit controller (pictured below), the controller will display the FAIL at the bottom of the homescreen if it’s in an alarm state:

An EZ-Zone displaying FAIL in this situation most likely indicates that the chamber’s temperature is higher than the limit set on the EZ-Zone. To adjust the high limit, press the green button until you see “Lh.S1” displayed in green at the bottom; from here you can adjust the high limit setting using the arrow buttons:

An EZ-Zone displaying FAIL in this situation most likely indicates that the chamber’s temperature is higher than the limit set on the EZ-Zone. To adjust the high limit, press the green button until you see “Lh.S1” displayed in green at the bottom; from here you can adjust the high limit setting using the arrow buttons:

The other limit controller model most commonly used with AES chambers is the Love Evco controller . With these controllers the light in the top left of the controller screen labelled “Out1” will switch off and an error symbol will show if the limit controller is preventing the chamber from heating as pictured below. To adjust the high limit, press the Set button and use the arrow keys to change the limit setting.

Checking the PCB

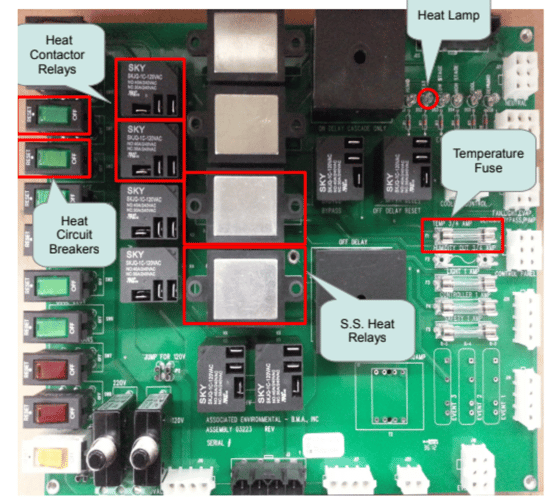

After verifying that the main controller and limit controller aren’t the issue, you’ll want to check the chamber’s main circuit board. Depending on your chamber model this will either be behind the side panel closest to the controller or under the top panel above the chamber’s interior. A list of heating-related components to check on the board are listed below:

- Make sure that the light labelled “Heat” is lit up when the controller is calling for heating.

- Check to see if any of the fuses on the board have blown, particularly the ¾ Amp fuse labelled “Temp”.

- Make sure none of the breaker switches on the board have switched off, they should all be in the “Reset” position.

Next Steps

Two additional components to inspect are the heat link fuses and the heaters themselves. The link fuses will be located behind the chamber’s baffle, usually either on the side of the evaporator coil or next to the circulation fan; an example of what these look like is attached below. If either of these link fuses have blown the chamber’s heat control will not work until the fuse is replaced.

An example of what the heaters typically look like is included in the picture below as well. The main things to check for with these are to make sure their wires are all properly connected and that they don’t have any tears or corrosion on them. If you have a multimeter available you can also measure the resistance heaters themselves to determine if they’ve failed; AES Support will be able to provide you with an expected resistance reading for the heaters in your chamber for comparison.

For additional assistance, please reach out to AES’ support or service team. You can reach us by phone at 978-772-0022 and by email at support@associatedenvironmentalsystems.com