This FAQ Troubleshooting Guide refers to chambers built after 2008 with an F4T controller. Please contact technical support if your chamber is an older model. All corresponding images are linked and are listed at the end of the article.

WARNING: RISK OF ELECTRIC SHOCK AND BURNS. Only qualified personnel should perform any repairs to your AES chamber. Please make sure that the chamber is turned off and unplugged before performing any maintenance or repairs.

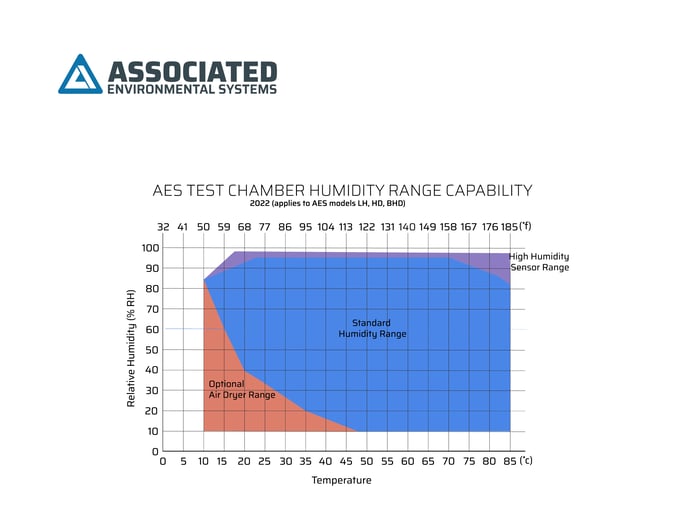

Humidity Range

The first thing to check is to ensure that the humidity setpoint you’re trying to reach is within the chamber’s specified humidity range; the chart below shows the humidity setpoints every standard AES humidity chamber can reach at any given temperature. The blue section represents the range any humidity chamber can reach, while the red and purple sections only apply to chambers purchased with the air dryer and high humidity sensor options, respectively.

Water Supply

Water Supply

If the setpoint you’re trying to reach is within the range pictured above, the next thing to check would be the chamber’s water supply.

What type of water should I use?

You should be using either demineralized or single-distilled water; water that’s too purified (such as deionized or double/triple-distilled) or not purified enough (such as unfiltered tap water) will cause humidity control issues and potentially clog up the chamber’s water pipes. Read more here.

Checking the Demineralizer Cartridge

If your chamber has a demineralizer filter cartridge then you shouldn’t need to worry about the quality of the water going into the chamber (as long as it isn’t already too purified before reaching the filter), you would just need to make sure that the cartridge is still working properly and doesn’t need to be replaced. The beads inside the cartridge will change from purple to yellow as they’re used up so you can tell whether a cartridge needs to be replaced by its color:

What is my correct PSI of the water input?

Please refer to the back of the chamber to establish PSI input. (If you have an external tank, please ensure this is filled during chamber use). It is on a sticker next to the humidity system water connection. Also, verify all water related valves are open and connected to the right ports.

Controller (F4T)

What can I check on the controller to see if my humidity is working correctly?

Firstly, you will want to make sure that the control mode above the humidity setpoint is set to “Auto” and not “Manual” or “Off”; if the controller is displaying either of the latter two options then you can set it “Auto” by tapping the three white dots in the top right corner. The controller should also be displaying a percentage in at least one of the two PWR bars below the humidity setpoint; the top bar is for humidity and the bottom is for dehumidification. If you’re unable to set the humidity loop to “Auto” mode, or if there isn’t a percentage showing at the bottom when the chamber should be raising/lowering humidity, then the issue is with the controller itself.

Controller (F4)

What can I check on the controller to see if my humidity is working correctly?

If your chamber has an older Watlow F4 model for a controller, the main thing to check for is to make sure the appropriate indicator light on the side of the controller face is lighting up. If the chamber is set to raise its humidity, you should see the light marked 2A lit up; 2B is the output light for dehumidification. If these lights are not coming on then the issue is with the controller itself.

Next Steps: Steam Generator and Electrical Circuit

I’ve completed the steps above and the chamber is still not reaching the required set point.

If there appears to be a request for humidity coming from the controller, the next area to check would be the thermal safety switch on the steam generator. On most AES chambers the steam generator will be located behind the chamber’s panel on the side closest to the controller as pictured below; on some larger models the steam generator(s) will be in the bottom compartment of the chamber.

If that switch continuously trips then that usually indicates there’s not enough water flowing from the external float tank into the steam generator; the best ways to try to rectify this are to raise the water level in the float tank and to clean out the pipe in between the float tank and steam generator by either flushing water through it or feeding compressed dry air into it in order to clear out anything that may be obstructing water flow.

I have reset the steam generator, and powered on the machine; I am still not getting humidity in the chamber.

After checking the suggestions above, the next step is to examine some of the humidity components on the PCB circuit board (Note: not every AES chamber model has one of these boards in place, if your chamber has a different wiring set-up please reach out to support for information on your chamber’s humidity components). If the chamber does have a PCB in place it will most likely be either behind the same panel as the steam generator or under the top panel of the chamber.

The components to check on the board are illustrated in the diagram below; the chamber needs to be on and running while checking these so please use caution and please do not touch any of the elements. Firstly you will want to check whether the humidity fuse has blown and whether any of the breaker switches tripped into the OFF position. You will also want to confirm that the Humidity light on the board is coming on when the controller is calling for a humidity change, this will confirm whether the board is communicating properly with the controller.

Another component on the board to check is the humidity relay (circled in blue below); this relay is removable from the board so you can try switching with the other relay next to it (circled in red) to see if the humidity starts working in that case; if it does then that will confirm the relay is the issue. The other relay is for heating so if you start heating issues after switching them then that will confirm a relay failure as well. Some chamber models will have two relays each for heat and humidity, if that’s the case you can try switching both sets of relays. Just be sure to power off and unplug the chamber before switching these and be careful removing/connecting the relays to the board as their connectors can be stripped fairly easily.

Exhaust Port

Most chamber models will have a short stainless steel exhaust pipe on the side of the chamber (as pictured below) to prevent overpressurization in the chamber, if this port is covered or obstructed in any way that can cause humidity control issues as well.

If none of the suggestions above resolve the issue or if you require any further information or clarification, please reach out to AES support. You can reach us via email at support@associatedenvironmentalsystems.com, via phone at 978-772-0022, or through the live chat on our website.